Frequently Asked Questions

RC, SC & CT Current Transformer Ratio Modifications

The current ratio between the primary and secondary winding is defined by the following formula:

Ns x Is = Np x Ip

Where:

Ip = Primary Current

Is = Secondary Current

Np = No. of turns on the Primary Winding

Ns = No. of turns on the Secondary Winding

Example:

On a 300:5 current transformer,

Is = 5 Amps when Ip = 300 Amps,

the number of primary turns is 1.

Ns x 5 = 300 x 1

Ns = 60

The ratio of the current transformer can be modified by altering the number of secondary turns. Forward or backwinding the secondary leads through the window of the current transformer will add or subtract secondary turns respectively.

By adding secondary turns the same primary current will result in a decrease in secondary current output. By subtracting secondary turns the same primary current will result in greater secondary output.

Example:

On a 300:5 current transformer, if a 325:5 current ratio is desired it is necessary to add five turns to the secondary winding.

Ns x 5 = 325 x 1

Ns = 65Deducting 5 secondary turns will create a transformer with a current ratio of 275:5.

Ns x 5 = 275 x 1

Ns = 55

SC Series Ratio Modifications

Primary Turn Ratio Modifications

Formula:

Ka = Kn x Nn /Na

Where:

Ka = Actual Transformer Ratio

Kn = Nameplate Transformer Ratio

Na = Actual Number of Primary Turns

Nn = Nameplate Number of Primary TurnsThe ratio of the current transformer can be modified by adding more primary turns to the transformer. By adding primary turns, the current required to maintain five amps on the secondary is reduced. (Example: A 100:5 current transformer designed for one primary turn.)

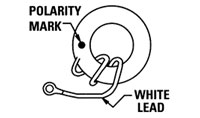

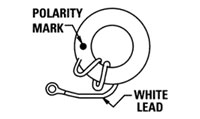

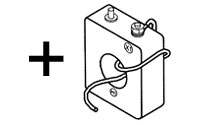

Square Case Transformer Polarity

Secondary Turn Ratio Modification

The current ratio between the primary and secondary winding is defined by the following formula:

Ns x Is = N<p x IpWhere:

Ip = Primary Current

Is = Secondary Current

Np = No. of turns on the Primary Winding

Ns = No. of turns on the Secondary WindingThe ratio of the current transformer can be modified by altering the number of secondary turns. Forward or backwinding the secondary leads through the window of the current transformer will add or subtract secondary turns respectively.

By adding secondary turns the same primary current will result in a decrease in secondary current output. By subtracting secondary turns the same primary current will result in greater secondary output.

VA is the Volt-Amp Rating of the current transformer.

The VA rating is an indication of the maximum burden (resistive and/or inductive load) that can be placed across the secondary connections of a current transformer operating at rated current. A burden above the VA rating may result in core saturation and measurement inaccuracy.

The VA rating of the current transformer is determined through two straightforward equations.

Power = Current x Voltage e.g. VA = Is • V

Voltage = Current x Resistance e.g. V= Is • R

Where:

VA = Volt-Amp Rating (VA)

Is = Secondary Current (Amps)

R = Burden (ohms)

Combining these equations results in:

VA = (Is)2 • R

In some cases, required VA ratings are listed on the device the current transformer will connect with, ie. a meter, relay, etc. Typical internal meter burdens are in the milliohm range.

The load, or burden, in a CT metering circuit is the (largely resistive) impedance connected to the secondary winding. Typical burden ratings for IEC CTs are 1.5 VA, 3 VA, 5 VA, 10 VA, 15 VA, 20 VA, 30 VA, 45 VA & 60 VA. ANSI/IEEE burden ratings are B-0.1, B-0.2, B-0.5, B-1.0, B-2.0 and B-4.0. This means a CT with a burden rating of B-0.2 can tolerate up to 0.2 Ohms of impedance in the metering circuit before its output current is no longer a fixed ratio to the primary current. Items that contribute to the burden of a current measurement circuit are switch-blocks, meters and lenghty secondary conductors.

The most common source of excess burden in a current measurement circuit is the conductor between the meter and the CT. Often, substation meters are located significant distances from the meter cabinets and the excessive length of small gauge conductor creates a large resistance. This problem can be solved by using a larger gauge secondary wire, or a CT with 1 ampere secondary which will produce less voltage drop between a CT and its metering devices (used for remote measurement).

In certain applications, such as in metering applications, accuracy of the current transformer is of concern. For a metering class transformer, a description will appear as follows:

(Accuracy)-B(Burden) e.g. 1.2-B0.5

The above example has a 1.2% accuracy at 0.5 ohm burden.

When a higher rating factor is needed, the designer should consider a relay class transformer. A relay class transformer will guarantee the transformer will not saturate at 20 times the rated current and be within +/- 10% accuracy. This allows a meter to detect larger fluctuations in the primary current.

The relay class transformers are classified as follows:

20 • (Rated Secondary Current) • (Burden) = Relay Class Rating

Example:

20 • (5 amps) • (1.0 Ohm Burden) = C100

MCT has developed many different types of relay class transformers in the past for a variety applications.

Rating factor is a factor by which the nominal full load current of a CT can be multiplied to determine its absolute maximum measurable primary current.

Midwest Current Transformers constructs most of its transformers from Cold-Rolled Grain Oriented Electrical Steel (CRGO). The CRGO electrical steel is rolled into the customer’s inner and outer diameter dimensions, allowing tight construction between layers and precise dimensioning.

CRGO electrical steel is an iron-silicon alloy that was developed to provide the low core loss and high permeability required for more efficient and economical electrical transformers. CRGO electrical steel is usually less than 2mm thick, has a silicon level of 3%, and is coated to increase electrical resistance between laminations, and to provide resistance to corrosion and rust.

Additionally, the steel is processed in such a way that the optimum properties are developed in the rolling direction, due to a tight control of the crystal orientation relative to the sheet. The special orientation of the crystals within the steel increase the magnetic flux density by approximately 30% in the coil rolling direction. This allows cores to have a higher efficiency and smaller size.

Midwest Current Transformers does not have minimum order requirements, we are here to get our customers the products they need when they need them.

We have a standard one week lead time for most orders. Orders will ship out one week after the date the purchase order is received. If you need something sooner, give us a call, orders have gone out as soon as same day. Same day build and ship may be possible.

We accept all major credit cards, wire transfer, Ach payments and you can apply for net 30 credit terms with us.

Yes, we are able to drop ship orders at no extra charge.

No, you can purchase directly from us.

Worldwide Leader In Current Transformer Products

Midwest Current Transformer has been an industry leader in design and production of current transformer products for over 50 years. Our focus is to build quality products designed to meet your needs. You may choose from any of our standard products or we can design and build a custom solution specifically for your application..

Superior Goals and Higher Expectations

It is the goal of Midwest Current Transformer to maintain its position as a worldwide industry leader . . .